Release liner

Ximo™ – Ultra-Thin & Reliable Release Coating

With very simple chemistry Plasmalex’ offers an ultrathin and ultraclean release coating; Ximo.

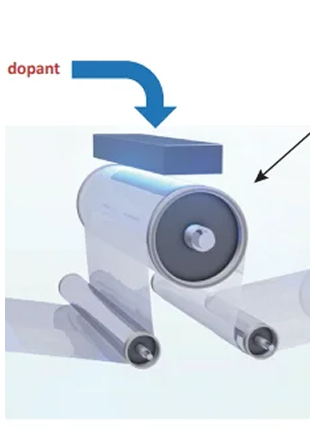

The patented release liner Ximo is manufactured on our Bluemach 2000 machine in a cleanroom environment.

Reliable & Consistent Performance

Reliable and predictable results

Consistent and stable release performance for several films and polymer substrates

Highly reproducible process ensuring consistent quality

Smooth release, no zippy effect, avoiding marking of the product and ensuring consistent quality

Reusable & Efficient Coating Solution

Reusable, very coherent, and anchored coating; keeps its properties after re-use, reducing waste and optimizing production efficiency

Long shelf life of treated products ensuring stability over time

Minimum transfer of silicone (very low level of extractables)

Versatile & Customizable Release Coating

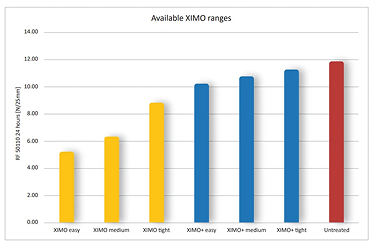

Tunable release properties: Ximo’s release properties can be adjusted or tailored to meet specific requirements, allowing for customization and versatility in various applications

Ultra-thin release coating

Very simple chemistry, only one molecule used (no catalyst, CRA…)

The coating is compatible with composite applications (pre and post-curing)

Ximo is the most efficient solution for a wide variety of casting and transfer applications, including PU casting, film wrapping, and transfer printing

Ximo™ – Industrial-Scale Precision Release Liner

The Only Atmospheric Plasma Release Liner for High-Precision Applications

Ximo is the only atmospheric plasma release liner available on an industrial scale for applications where consistency and precision are essential.

Tunable release force by varying the coating thikness between 1 and 10 nm

Latest Case Studies

Application

Plasmalex is your reliable partner for a complete range of

state-of-the-art industrial solutions to increase your product capabilities.

Overview

We offer cutting-edge solutions for creating water-repellent, PFAS-free nanocoatings using Plasma-Enhanced Chemical Vapor Deposition (PECVD).

Mission

As a fully integrated research, development and engineering group, Plasmalex provides complete solutions for nanoscale surface treatment with the lowest possible environmental impact.

Plasmalex is your reliable partner for a complete range of state-of-the-art industrial solutions to increase your product capabilities.