Vacuum and atmospheric plasma technology

Vacuum & Atmospheric Plasma

Plasmalex offers turnkey vacuum and atmospheric plasma solutions, delivering both chemistries and equipment, and customized solutions.

Advanced Surface Treatment Technologies at Plasmalex

Innovation is always a core aspect of our vision and operations. As a leading player in the industry, Plasmalex invests in research and development to implement advanced technologies. A century-long dedication to new ideas makes the company consistently deliver new coating compositions and the most progressive equipment systems, which become industry benchmarks and define its further development.

We are inspired to continue to develop surface treatment technology to make breakthroughs in the future. Our portfolio of advanced technologies includes

Plasma Enhanced Chemical Vapor Deposition (PECVD)

At Plasmalex, we specialize in advanced PECVD technologies that enhance surface properties, improve material performance, and create highly functional coatings that meet specific industrial needs.

PECVD technology is used to achieve higher-quality coatings in the electronics, automotive, and aerospace industries. This process allows for procedures to be executed in a controlled manner producing quality, uniform thin coatings that increase the efficacy and durability of parts. The biggest advantages of this technology are improved performance, low-temperature deposition, and highly controlled film properties.

Biocompatible Coatings

Plasmalex offers advanced biocompatible coating solutions that enhance the performance, longevity, and safety of medical devices used in implants, diagnostics, and therapeutic applications.

We provide bio-compatible coatings for various medical applications and implantation. These coatings are intended to produce protective and durable structures that provide a high quality and safe performance inside the human body.

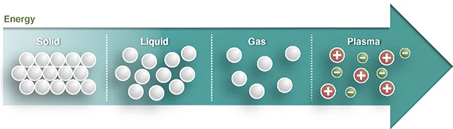

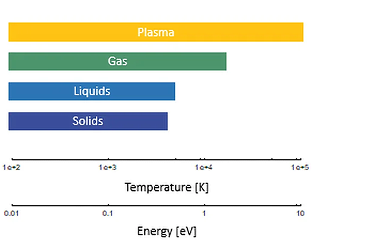

What is Plasma?

Plasma is considered the fourth state of matter after solid, liquid and gas. By adding energy matter can be transformed from solid to liquid, from liquid to gas and from gas to plasma.

At the plasma stage matter exists in the form of a gas of ions and free electrons and is highly electrically conductive. Although plasma is abundant in the universe, natural occurrences are relatively rare on earth. Lightning, static electricity and auroras are the primary sources of natural plasma.

Benefits of plasma technology for surface treatment

Plasma technology for surface treatment solutions offers several benefits:

High precision surface cleaning, activation and etching. Very consistent nanocoating quality The process penetrates in the molecular level of material. A low process temperature, important for sensitive substrates and material handling Low chemistry consumption Environmentally friendly production process

Low environmental footprint

Compared to conventional chemical coatings Plasmalex’ processes guarantee the lowest environmental footprint

The lately developed PlasmaGuard® coating chemistry is halogen free.

Moreover, thanks to their high filtration system, Plasmalex machines are safe in use.

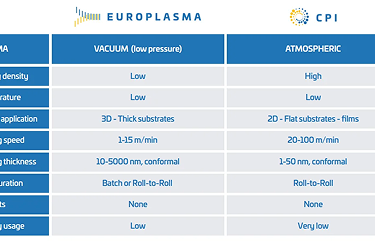

Vacuum versus atmospheric plasma

Unique Plasmalex offering

Customer tailored solutions for static as well as roll-to-roll applications Conformal treatment of up to 2 m wide rolls Unique industrial-scale test & job coating capabilities Experienced team of plasma experts Global service support network Extensive portfolio of patents protecting machine design, processes and methods for plasma deposition

Biocompatible Coatings

Plasmalex offers advanced biocompatible coating solutions that enhance the performance, longevity, and safety of medical devices used in implants, diagnostics, and therapeutic applications.

We provide bio-compatible coatings for various medical applications and implantation. These coatings are intended to produce protective and durable structures that provide a high quality and safe performance inside the human body.

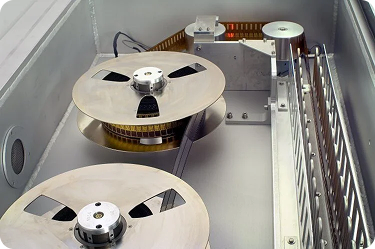

Pioneering Industrial-Scale Plasma Solutions

We are unique in offering industrial-scale solutions for both static as well as reel to reel PECVD equipment & chemistry 30 years of experience allowed us to optimize machine & process designs for low pressure plasma applications We have built an extensive track record of customized solutions With multi-stage coating technology

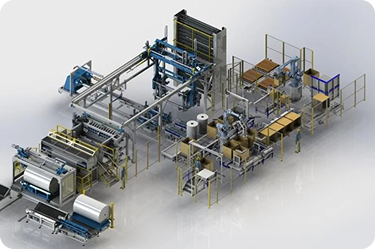

Turnkey Solutions

Our solutions include the development of specific chemistry and contract

manufacturing services on our own equipment. In partnership with our sister

company Spoolex, we can provide integrated production lines that are fully turnkey.

Our integrated production lines include:

automatic loading and unloading

turret slitter/rewinders

automation of upstream and downstream processing

World-Leading Technology for Industrial Roll-to-Roll Atmospheric Plasma

We have a patented electrode/gas diffusor assembly which ensures:

Control of the chemistry

A homogeneous ultra-thin coating (1-10 nm) of over 2 m width

Reduced electrode fouling

No contamination of the product by plasma generated powders

Advancing Atmospheric Plasma with Precision & Innovation

Industrialized atmospheric plasma applications come with challenges such as inerting, gas handling, power management, and ensuring coating quality and homogeneity. To overcome these, we prioritize R&D with continuous research on process parameters, controlling up to 89 interconnected plasma factors, and optimizing generator technologies. Our focus on plasma chemistry provides a sustainable alternative to traditional wet chemistry, ensuring stable and high-quality treatments.

Latest Case Studies

Application

Plasmalex is your reliable partner for a complete range of

state-of-the-art industrial solutions to increase your product capabilities.

Overview

We offer cutting-edge solutions for creating water-repellent, PFAS-free nanocoatings using Plasma-Enhanced Chemical Vapor Deposition (PECVD).

Mission

As a fully integrated research, development and engineering group, Plasmalex provides complete solutions for nanoscale surface treatment with the lowest possible environmental impact.

Plasmalex is your reliable partner for a complete range of state-of-the-art industrial solutions to increase your product capabilities.