Plasmalex surface treatment solutions for filtration

Superior Protection for Electronics

In filtration, uniform quality and performance is of utmost importance. Plasmalex’ surface treatment solutions increase your filter performance as well as extend the lifespan of your filtration product.

Enhanced Filtration Performance with Plasma Coatings

Plasmalex vacuum plasma technology deposits ultra-thin plasma coatings with various properties into the core of complex and porous structures and minimizes pressure drop. Filtration is one of Plasmalex’ s primary segments for vacuum plasma.

Plasmalex has a solution for several applications in filtration.

Electrets

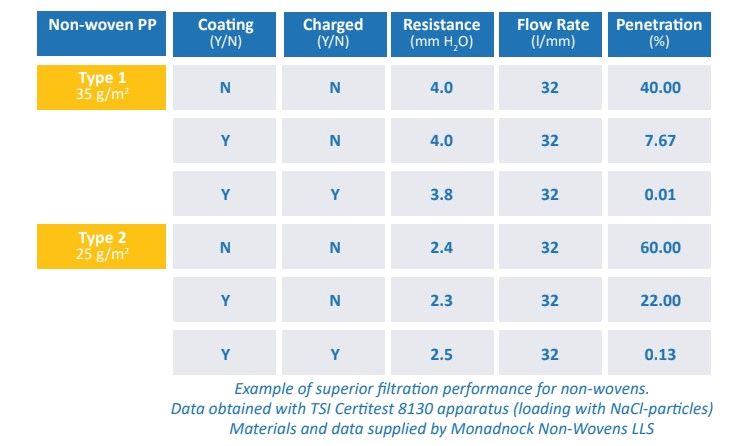

Plasma coatings provide a very high level of filtration of ultrafine solid particles with a minimal effect on pressure drop. It also increases the charge lifespan. This configuration is used for FFP2 / FF3 masks, ..

Industrial filtration

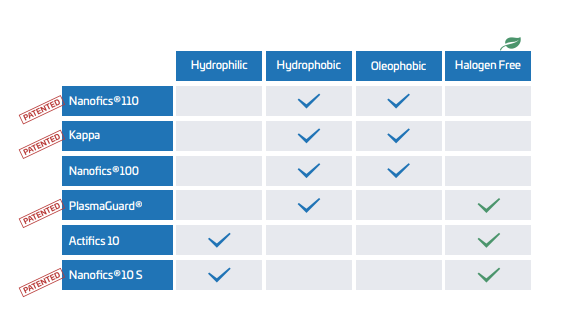

Nanofics 110 improves filtration of oil droplets for gas turbine filters and gas chromatography

Blood filtration

Hydrophilic Nanofics 10 S improves blood filtration performance..

Air-filtration

Plasma coatings provide a very high level of filtration of ultrafine particles (< 0.3 µm) for HEPA filters, car filters, air purifiers, HVAC and clean room filters.

Partner SCS Specialty Coating Systems

Europlasma is partnering with Specialty Coating Systems (SCS), a global leader in conformal coating services and technologies, to expand their coating portfolio to include PlasmaGuard™ coating services.

Superior Nano Coatings for High-Efficiency Filtration

Plasmalex’ s Technology offers highly technical and repeatable processes. Coatings are permanent and flexible.

Plasma coatings preserve substrate properties (such as breathability, acoustics, …)

Plasma coatings are ultra-thin. For filtration, the typical thickness of Plasmalex coating is 5-100 nm

Why choose plasma nanocoatings in filter applications?

Plasmalex nano coatings ensure superior filter efficiency with minimum pressure drop.

Coatings improve mechanical filter properties to reach the best filter performances combined with a low Total Cost of Ownership in your production lines. You need less material to obtain a higher filter efficiency.

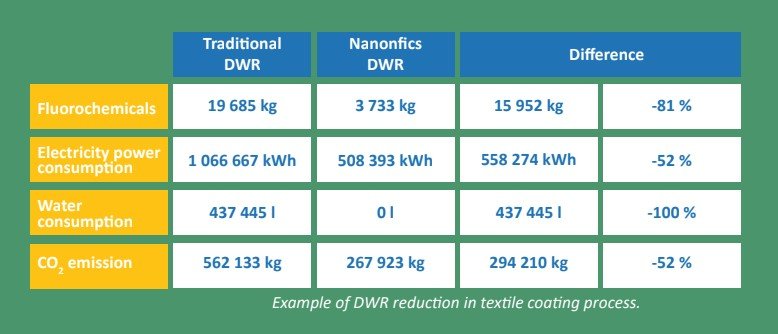

Green technology

Plasmalex processes ensure the lowest environmental footprint compared to traditional chemical coatings, reducing DWR coating chemicals by 80%, water consumption by 100%, and energy usage by 50%. Our latest PlasmaGuard® coating chemistry is halogen-free, and with a high-efficiency filtration system, Plasmalex machines offer both safety and sustainability.

Plasmalex solution overview

Plasmalex offers turnkey plasma solutions for filtration, delivering both chemistries and equipment.

Plasmalex surface treatment

Cleaning: removal of molecular contamination layers from a surface.

Etching: removal of surface material up to 1 µm.

Activation: chemical modification of surface prior to gluing, painting or bonding.

.)Plasmalex machines

.)Plasmalex coating portfolio

Latest Case Studies

Application

Plasmalex is your reliable partner for a complete range of

state-of-the-art industrial solutions to increase your product capabilities.

Overview

We offer cutting-edge solutions for creating water-repellent, PFAS-free nanocoatings using Plasma-Enhanced Chemical Vapor Deposition (PECVD).

Mission

As a fully integrated research, development and engineering group, Plasmalex provides complete solutions for nanoscale surface treatment with the lowest possible environmental impact.

Plasmalex is your reliable partner for a complete range of state-of-the-art industrial solutions to increase your product capabilities.